Delta Group required a large, structurally sound but removable wall built to protect an existing wall that had become damaged during ongoing works, due to vibration and other movements associated with construction, as well as from inclement weather.

“The goal was to have the wall in place to ensure the existing wall wouldn’t be damaged any further,” says Chris Grogan, Royal Wolf Regional Sales Manager for NSW/ACT.

Needs of our client

>24m x 12m protective wall

>Wall must be structurally sound

>Wall to be weatherproof

>Safety of persons on site

>Ability to remove wall when it’s no longer needed

Solution

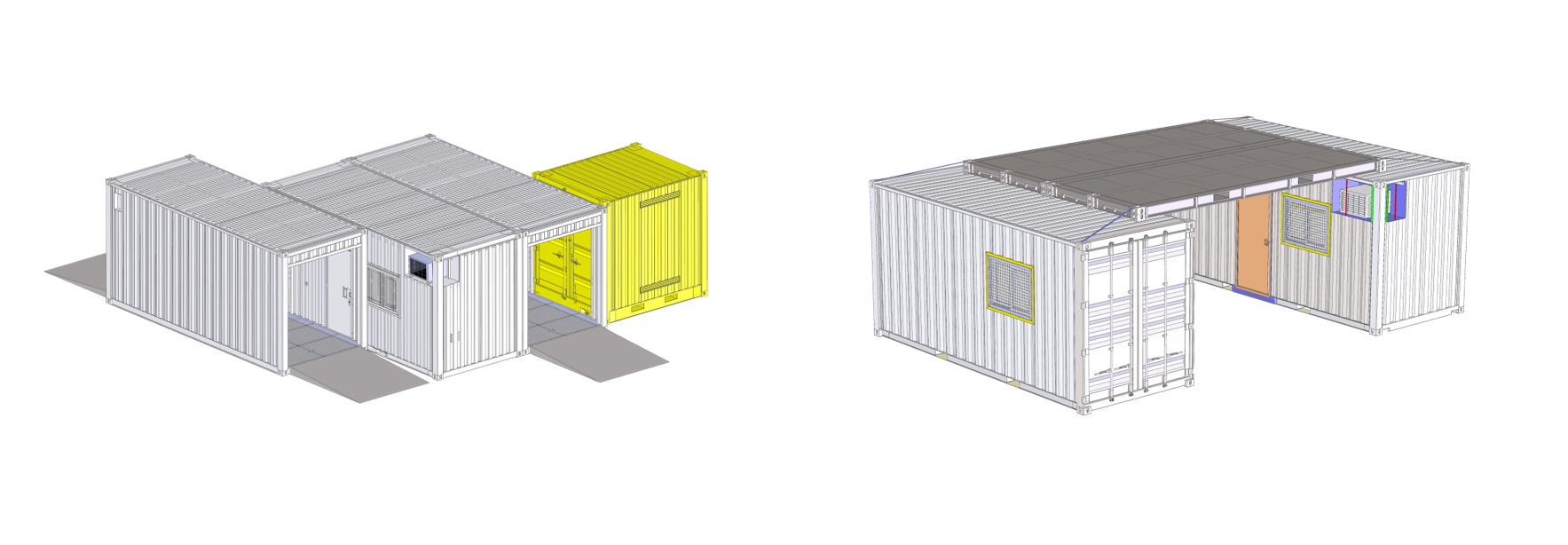

Several design and engineering analysis phases were completed to devise the safest and most secure solution. Royal Wolf engaged engineers to complete an analysis, while Delta Group’s engineers completed their own, before both came together to lock in the final triple stack design.

“Once we completed our site inspection, I presented Delta Group with a PowerPoint design of the set up, which included dimensions and their requirements, and once that was agreed to, we sent it for engineering analysis that covered off stability and any environmental factors that needed to be addressed for safety,” says Chris.

“We needed to cover 48 metres in length and 12 metres in height, so despite initially thinking we’d do a double stack, once we marked up the wall we needed to cover, we realised we needed to go up another level.”

Royal Wolf also completed a secondary site inspection to plan for the building of the wall. The inspection included Chris, Royal Wolf’s installation staff, Delta Group representatives and the crane crew.

“It was for the methodology to install,” says Chris. “We looked at where we were going to set up on the day for the cranes to put the containers and platforms in place, what size cranes we needed, as well as traffic management to ensure everyone coming in and out of the site could do so safely.”

Solutions provided

>Creative logistical solutions, including collaboration with Delta Group over needs, design and best practice

>24x 20-foot general purpose containers

>24x 20-foot concrete platforms

>12x 20-foot standard platforms

>Engineering analysis

>Safety plans and protocols

>Containers, concrete and standard platforms delivered on site

>Containers, concrete and standard platforms installed securely

>Project, including delivery, placement, safety and traffic management overseen and managed by Royal Wolf

Outcome

Installation was completed in two-and-a-half days, while the wall was constructed just under three weeks after Delta Group first contacted Royal Wolf, a time period that included four design variations.

Delta Group hired 24x Royal Wolf 20-foot general purpose containers, 24x 20-foot concrete platforms and 12x 20-foot standard platforms to construct the wall, with the concrete and standard platforms included for structural stability and safety, as per needs identified in the engineering analysis.

Working in collaboration with Delta Group and Borger Cranes, Royal Wolf orchestrated the installation from start to finish. This involved delivering all containers and platforms on site, sourcing the crane company to lift the containers and platforms into place and managing installation, implementing safe work methods and ensuring all persons on site were briefed on safety measures, checking all staff had the correct tickets (licences) to perform work, and traffic management.

“The key focus during installation was safety,” says Chris. “When all teams were on site, we ran a ‘toolbox’ every morning to go through what the procedures were for the day, discussed what was coming in and what trucks were arriving. We wanted to make sure everyone was clear on exactly what was happening.”

Delta Group was extremely satisfied with the final product. “The most impressive feedback we received from Delta was how well the project was managed from start to finish,” says Chris.

“We had some tricky days, including where it was raining and windy, so it was important our supervisors and team were across that but we were still able to complete it within two-and-a-half days.”

.jpg)