.jpg)

When designing their Rare Earth Processing facility in Kalgoorlie, Lynas Rare Earths needed a robust solution to house their control equipment, while also providing full visibility over their plant and offering a safe and comfortable working environment for their operators.

Through DIAB Engineering, Lynas Rare Earths approached Royal Wolf to develop a solution that could be constructed off-site but easily transported, then installed and commissioned on-site.

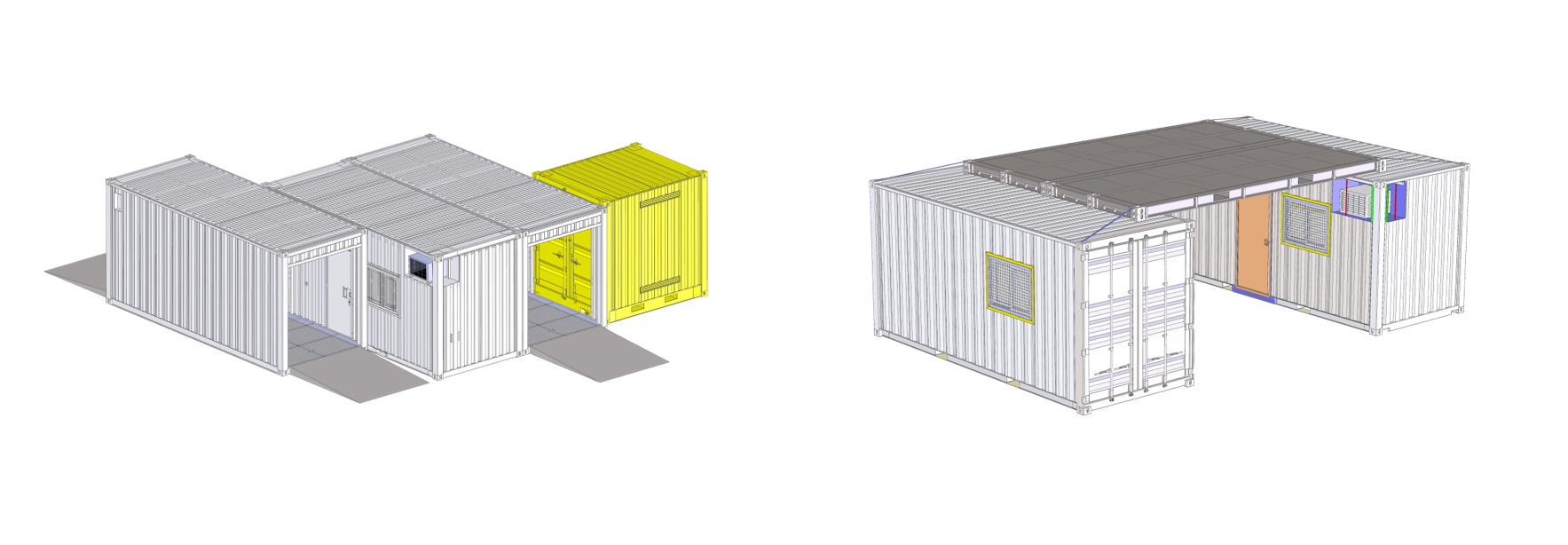

To achieve this, Royal Wolf combined two different sized shipping containers in an L-shaped configuration and installed three glass panels in a cantilevered structure to provide a 180-degree view of the processing plant. The remaining floorspace contained a kitchenette and storage space for control equipment.

Needs of our client:

- Structure to form an ‘L’ shape

- Glass panel to provide a 180-degree view outside

- Kitchen facilities

- Security and safety

- Fabrication off site with easy installation and integration on site

Solution

Royal Wolf’s in-house design and engineering team worked to ensure DIAB Engineering’s needs were met, despite facing particular challenges in creating the ‘L’ shape using a 20-foot and 10-foot container.

To create the shape and size required, Royal Wolf’s modifications team cut 1.2m out of the 20-foot container and then performed structural stability work to create a strong cantilevered section.

A structural assessment was completed by Royal Wolf’s engineers to determine what stability work needed to be done to adjust for the container’s new size.

“It was a complex project. As stability requirements had changed, we modified the container with new frames to ensure structural strength,” says Ranjith Raghunath, Royal Wolf Project Supervisor.

“Once the 20-foot container was at the right size and structurally safe, we added bridge clamps so we could join it with the 10-foot container to create the ‘L’ shape.”

Solutions provided:

- 1x 20-foot high cube container

- 1x 10-foot high cube container

- Container modifications to suit client needs, including:

- Containers joined together to form one large room in an ‘L’ shape

- Access door

- Kitchenette

- Office space with desk and chair secured to the floor to ensure no damage to the viewing window

- Floor penetrations to allow for client’s cabling and control equipment

- New vinyl flooring

- Electrical work

- Air-conditioning

- Paintwork - Transportable structure

- Easy connection system for on-site installation

Outcome

The security and functionality of the finished product as an observation deck and kitchenette is only the beginning.

“The benefit of choosing to build a structure like this with shipping containers is that it’s transportable,” Ranjith says.

“The containers aren’t joined permanently, so the bridge clamps can be taken out and the containers transported and then joined together again to create the same structure at a new location.”

Ranjith says he was filled with a sense of pride and satisfaction at being able to deliver such a complex project, with the client happy with the end result.

“I loved working on this project and doing something out of the box. There were lots of challenges, but with that comes a lot of satisfaction,” he says.

.jpg)

.jpg)